- cross-posted to:

- hackernews@derp.foo

- cross-posted to:

- hackernews@derp.foo

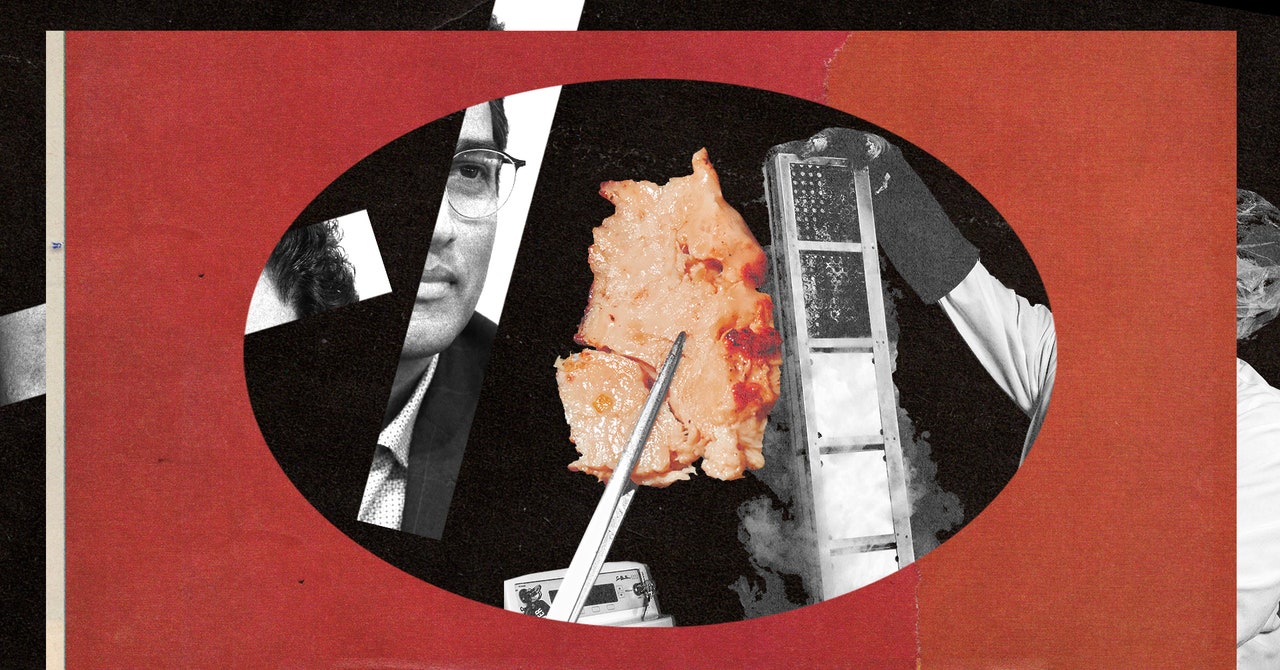

Billion-dollar cultivated-meat startup Upside Foods wants you to think the breakthrough chicken fillets it sells are made in a futuristic factory. A WIRED investigation tells a different story. On July 1, five diners sat down at the counter of the Michelin-starred Bar Crenn in San Francisco for an unusual meal. They had won a competition to become the first customers in the US to eat cultivated meat—real animal cells grown in bioreactors instead of a living animal. For a nominal price of $1, they tucked into two pieces of a cultivated chicken fillet made by the Californian startup Upside Foods, one of only two companies cleared to sell cultivated meat in the US. “I thought it was delicious,” says Oscar Merino, one of the diners. “The taste and the texture was incredible.”

Before their meal at Bar Crenn, Merino and the rest of the group toured Upside’s production facility across the Bay in Emeryville. They looked at neat rows of gleaming steel bioreactors, each one surrounded by a web of pipework. This factory—which WIRED visited in May 2022—is where Upside says it brews its cultivated chicken. The facility, Upside says, demonstrates to the world exactly how this novel meat is made. “We’re starting to show, from day one, what this whole industry is about,” Upside Foods cofounder and CEO Uma Valeti said in May 2022. “This is the opposite of very closely guarded food innovations.”

But former and current employees say the Emeryville plant tells a misleading story of how Upside’s chicken is made. In fact, sources say, the company’s flagship product—the juicy whole cuts of chicken served at Bar Crenn—are brewed, almost by hand, in tiny bottles. The huge bioreactors, those sources claim, simply aren’t capable of reliably brewing the sheets of tissue needed to form whole cuts of meat such as chicken fillets.

Even if it’s a labor intensive and expensive process, it’s helping alleviate suffering from animals. Not only that, this might help prevent the large scale greenhouse emissions and fresh water being diverted to factory farming animals. I’m hopeful for the technology to be able to scale.

And anyways they are able to grow cells in suspension for nuggets, hot dogs etc. it’s just the whole cuts that are causing the problem. I’m suspicious that the big-meat industry may have something to do with article because nothing here is super sensational to me other than the headline.

Hmmmmm… processed slurry of animal cells grown in a chemical bath vs tasty plate of beans and rice from the neighborhood taco truck.

Which is more affordable?

Which has less environmental impact?

(Something about lab-grown meat gets up my nose, and I can’t quite articulate why.)

That depends… what is the chemical bath made of? Is it much different than compost?

The most efficient food sources are still likely going to be bacteria and microalgae, followed by fungi… but a slurry of animal cells could come up close.

Apparently it’s not a given that cultivated meat has lower climate impact, see eg https://www.technologyreview.com/2023/07/03/1075809/lab-grown-meat-climate-change/

That’s sad 🥲

You’d think people learned from Theranos or Madoff …

Maybe they did, just not the right lesson.