Not a scientific test and not from every angle but interesting still.

The optimal structure is highly dependent on the type of loading: tension, compression, bending, shear, torsion, or combinations thereof. Thus, the results of these experiments are only valid for compression. For other load cases one either needs to do the specific experiments or run a topology optimisation, by e.g. a SIMP algorithm.

Or even in compression… if he had tested them with the weight moving along the printed z-axis.

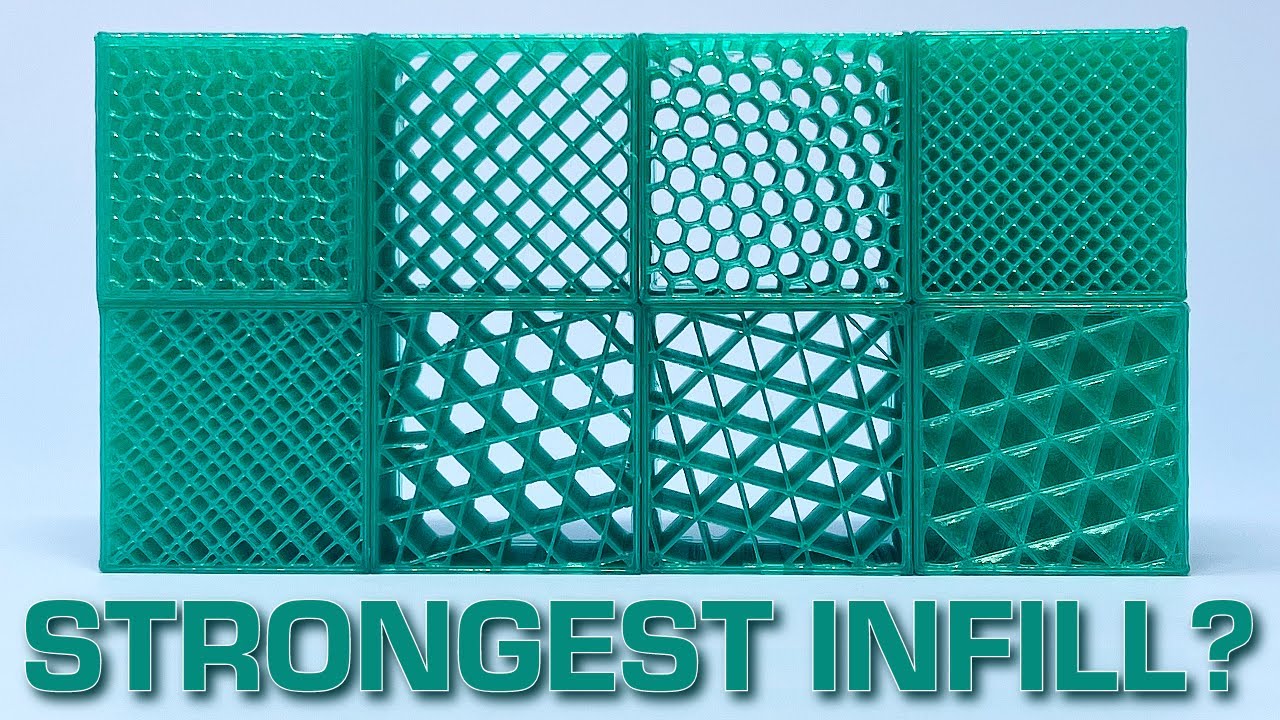

Rectilinear, grid, lines, honeycomb and stars and any other patterns like that aren’t going to be the same.

Also, things change again with part geometry- some paterns won’t be able to set up that neat crushing pattern on something like the wing he had in an example.

Edit: if he had included solid top and bottom layers as well- which is probably more typical of printing- the attached infil would behave differently.

This is interesting but the press is shifting as it’s pressing on the prints which tells me that the press itself isn’t even stable, so the conclusions are questionable at best.

There also are no top and bottom layers, and the test piece is larger than the surfaces of the press, so the results are only applicable for very specific loads.

Here is an alternative Piped link(s):

https://piped.video/IIS9UagZaWI

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source; check me out at GitHub.