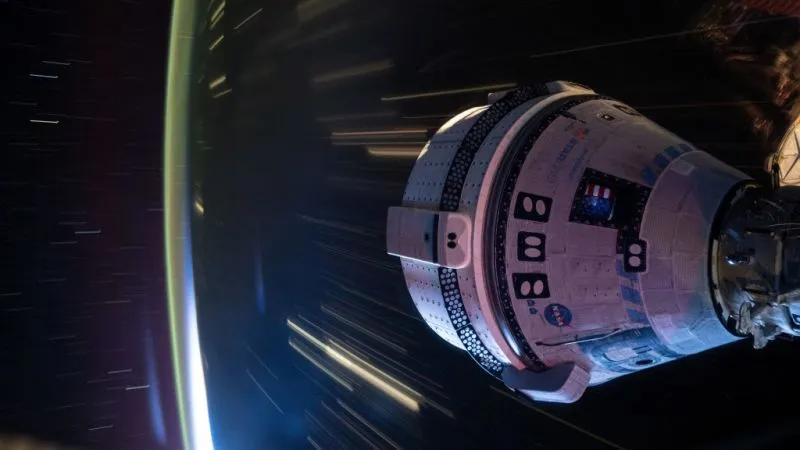

After weeks of troubleshooting and recent tests meant to replicate the issues plaguing Boeing’s Starliner spacecraft, NASA and Boeing officials still aren’t ready to name a return date for the two astronauts piloting the vehicle on its inaugural crewed test flight.

But engineers do finally have some possible answers about what ultimately caused some of the Starliner’s problems during the first leg of its trip, which included helium leaks and thrusters that abruptly quit working en route to the International Space Station.

The revelations come after Boeing and NASA spent the past couple of weeks working to understand the problem on the ground and prompted plans for some additional testing this weekend, which should serve as “icing on the cake” for understanding the issues, said Mark Nappi, Boeing’s Commercial Crew Program manager.

There’s people that can remotely diagnose and reprogram a device that’s almost outside the solar system.

And then there’s Boeing.

To be fair, you get a lot more leeway to make mistakes with something that doesn’t have people on board.

No one’s been on board the docked craft in weeks ;)

Hello fellow space engineers. I too know the root cause, but I won’t reveal it just yet. Perhaps after the weekend?

Officials said they were able to recreate how the thrusters in space deteriorated during flight with the ground tests. And the testing may have helped give engineers a better understanding of the issue’s “root cause”: Heat building up inside the thrusters may be causing Teflon seals to bulge, restricting the flow of propellant.

That testing has “given us additional confidence to undock in return,”** **Nappi said.

The article said it.

The hot parts aren’t compatible with high heat sounds right on par for Boeing

The root cause has been identified as “Being built by Boeing”

A modern commercial aircraft is one of the most complex machines humans have ever built, second only to a spacecraft. The average middle class American calls a plumber because their toilet internals broke.

Boeing is the only competitor with Airbus. The average middle class American doesn’t understand the capitalist concepts, let alone the corruption of them they now suffer.

This team, a small part of Boieing, put humans in space, approaching what was perhaps humanity’s greatest achievement so far. They had one issue. And, rather than cover it up and risk, especially now when such would be incredibly valuable, they communicated honestly, worked the problem, and will almost certainly bring this crew home safely.

As an engineer by education and computer scientist by trade, fuck all of you mindlessly crapping on this endeavor and their handling of it. What they’ve done is technically and ethically incredible.

They’ve been up there so long Zelensky is positioning troops, just in case.

Someone I know who worked on it told me what he thought the root cause was, I guess we’ll see if corporate shares the same conclusion.