When a simple one day job turns into a week-long project… Bonus points if you can guess the model.

I didn’t see what car this was. Did you mention it, and I just missed it?

You didn’t miss it, it’s a 1991 W124.

Cheap classic car. Pick two.

Cheap classic

That’ll be $1.

This is highway robbery.

Well played, but that’s pretty pricey for a Coke.

Cheaper than an 8 ball tho

8 balls are certainly classic

I only have 1 ball.

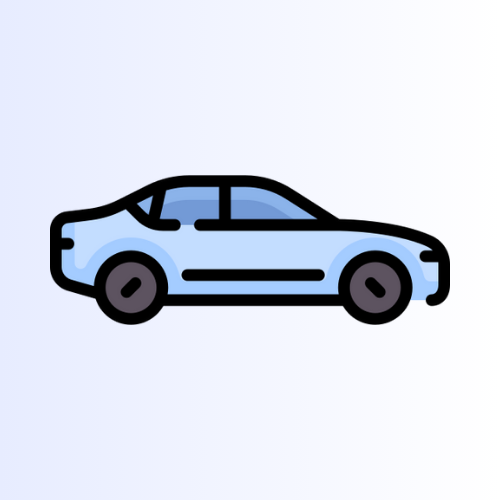

I don’t even know what part that is.

Pretty sure that is the top mount for a front spring based on the wide opening and the sloped side that is welded to the rest of the frame.

You got it. It’s the front right spring mount.

so a spring sprung through the metal and made a hole? I don’t really know cars at all

Haha no worries - the spring looks like this when it’s installed:

There is a lot of stress on the upper part because the entire weight of the car is resting on the springs. So over the years, cracks can form in the welds that attach the mount to the frame and moisture gets in and rust starts to form without being immediately visible. I just removed the underbody coating to treat the rust spots I could see, but it seems I was too late - it’s already rusted through.

oh yeah I can definitely understand the meme face now haha. That’s not good! Thanks for the explanation.

I was going to guess a body mount but your guess seems much better.

Looks like the top mount for the springs

I learned this the hard way with my 1974 MG B. I test drove it and looked it over from all angles and there didn’t seem to be any problematic rust. But lo and behold, digging into the floors a little bit they are pretty much rotten and now I’m doing a big restoration project. The lesson I learned the hard way, rust is 10x worse on the inside of the metal than it looks on the outside.

That’s because it’s like food rot you only see it on the outside when the inside is so advanced unless it’s using a different coating on the outside.

I’ve had 5 project cars and the worst was a Mazda. Rust ate the support channels from the inside so bad that it looked fine but couldn’t keep the wheels straight.

My most recent project is an old truck and it’s great. So. Much. Metal. Even if there’s rust you can easily cut it out and weld it up.

it looked fine but couldn’t keep the wheels straight

Damn, that’s pretty advanced rust. What happened to the Mazda?

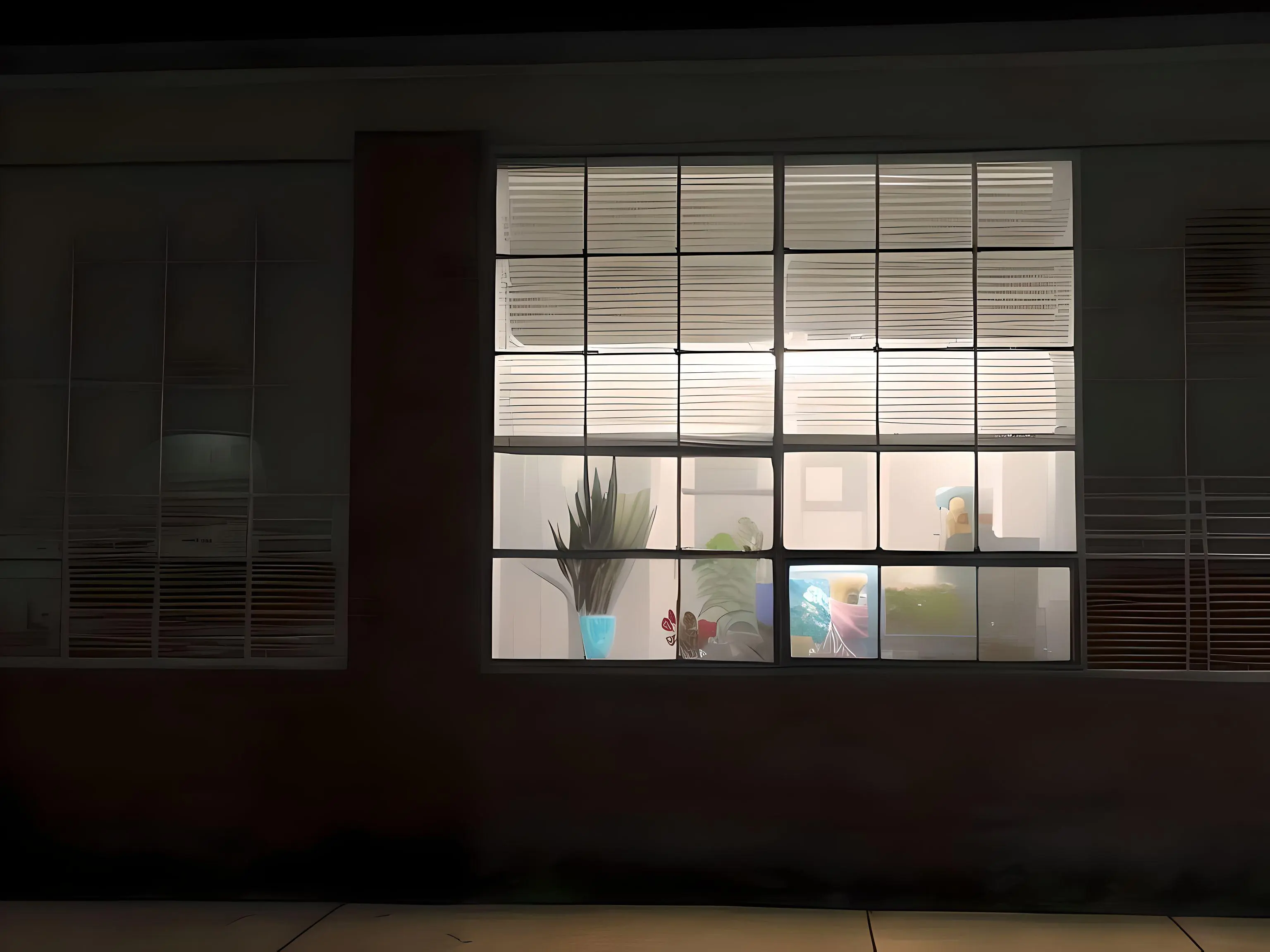

I think I got lucky, it seems that there’s enough material left to patch up the frame and weld a new spring mount on. The car is pretty solid otherwise but discovering this was not exactly a good feeling after driving it at 180 km/h on the Autobahn just the week before.

Alignment shop was on their 3rd attempt before they figured out the issue. You could press a screw driver against it and it would feel fine, but a good strike would go right through.

Engine only had 50k and the interior and body panels looked great. All new brakes and other items. It became a donor for a different car that some guy was restoring.

Yeah that’s some odd rust, looks like sold metal around it. I’d be concerned about that area and keeping things in the right spot. Good luck!

Thank you, though I think I’ll leave this one to the professionals. My guess is that a crack formed along the side of the mount and the previous owner just welded a piece on top. You can kind of see the spots in a few places. There was zero thought put into conserving the metal below, so it just kept rusting from the inside.

Cheap cars can be hit or miss. My cheap car has a lot of miles, but no rust. It also has no power steering. The pump was leaking bad so I just took the belt off. I can live with it for now. One day, I’ll get my ass in gear about it lol

Ironically the cheapest car I ever bought was also the most reliable I’ve ever had. It was a 2002 Mitsubishi Colt/Mirage (not the ugly one) for just 200 Euros. Still miss it.

Bondo baby…?