Thank you both! Hopefully get to come out with even more crazy fun ideas soon!

The Meep and the Merp of www.skree.us, www.etsy.com/shop/TheBigSkree, and Skree LLC.

I make keyboards, hydroponics that no one has seen and lots of cool pcb / mass production solutions. Reach out if you want to discuss anything.

Thank you both! Hopefully get to come out with even more crazy fun ideas soon!

Not that I’m aware of but the DRC systems should be able to make it pretty clear if there’s track issues.

There are circuit / electrical simulators but that’s a very complicated solution for keyboard designs that tend to be simplistic.

Matrix circuit designs are not much to be worried about. If you had a design in question I’m sure someone including myself would be willing to look at it.

What kind of plastic? If PLA 3D Gloop PLA works amazing. Otherwise hotglue, or my suggestion is don’t do single key pcbs / handwiring (ad) I make flexible pcbs for curved keywells (specifically used them on my dactyl keyboards I’ve sold, hundreds in the wild without any issues! www.skree.us or etsy.com/shop/thebigskree if you’re interested in that. (I ship internationally but it can sometimes take a while to arrive).

If the micro controller works with the software (ZMK / QMK / KMK etc) then yes, it works. Both of those would work.

Enjoy?! Heck yes. What a build!

Wired I can do more of. Just order two I have spares for the extras I’ll gladly just include. The actual cost in time is minimal for the extras.

As in 5 rows 7 columns? My flexible pcbs can be linked together for infinity columns.

https://www.etsy.com/listing/1367143291/dactyl-flexible-pcbs-4-and-5-high I’m out of populated 5r pcbs but I just got the pick and place machine populating diodes (I’m short on hotswaps but they’re super easy to solder).

Kill your board? No! They’re all data pins, so there isn’t current to kill anything unless you short to the PCB or a battery somehow!

I make flexible pcbs with hotswap for dactyls (and other curved / flat keyboard production). They save oodles of time, and make troubleshooting easier too! All you need is a little hotglue on the edges to lock the pcb fully in place (I have a screw version produced too just need to get a good source of screws to include).

Handwired builds, especially uninsulated are more prone to shorts that will cause unexpected switch behavior. PCBs even per key help minimize that risk.

Not 100% sure on if you can easily get this consistent. I know that there are ways of dying resin post print though.

I wonder if you can just get evenly tinted semi-clear automotive for it.

SK6812 Mini-E (they’re the big legs, but I don’t know the component name difference).

They can be per key (not supported on ZMK currently) or just treated as up facing underglow. BUT! The biggest concern I’ve had is the realization thaht all RGB boards on the market that use SK6812 in bulk don’t seem to consider the total peak power consumption.

One color can peak at 12ma at 5v. They’re often ran at 3.3 or 3.7v. 3 colors per led for 36ma per led. So on sofie type boards where there’s ~30 keys per half you’re pulling 1.08ma if you ran the leds at max white. This would be HIGHER if they’re run on 3.3v or 3.7v due to the relationship between wattage and voltage. Yet! They’ve worked fine. I’ve had good success.

Going forward I’m swapping to SK6805 surface mounted leds. I’ve got the pick and place running, and the goal is to have per key rgb with underglow. That would almost 1/3rd the amperage requirements. Also gives me a little more board space I’m hoping.

Ideally, I’ll have non-rgb options, up facing perkey rgb, underglow, and up and underglow rgb options (probably 2 independent rgb channels aka underglow has its own data pin). All in either Choc v1, MX, and whatever else I decide to support.

I’ve got a working “screw” mount solution that works! The problem is with the pcbs fitting super well (model dependent) (I’ve based on the standard dactyl) why bother using lots of screws when a little hot glue does the job. My first versions were wrongly sized and I ended up being extra cautious with lots of extra glue to ensure there’s never a issue with pcbs coming free, but at this point I’ll either cut the number of screw points down, or honestly supply it but not use it myself.

The nice thing with getting access to production equipement (my designs are all about saving my time in production) you get to save that time too.

Sorry for the silly long response!

It’s resin from JLCPCB. My small resin printer just can’t do a 5x6 sadly. The first transparents I had done was with PETG.

Sadly, JLCPCB doesn’t do tinted black, but honestly a clear coat with a little black alochol dye probably would do the trick.

I was blown away with the quality from JLCPCB. It’s not that expensive but shipping hurts. Holes aren’t perfect, but my switch dimensions worked great surprisingly. I need to do a little more work getting the threaded inserts I have fully working (might have to drill potentially because I didn’t expect the oval circles). Their texture really confuses me. I legit don’t know for sure what technology they’re using for their resin prints.

It can be a pain. That and tuning supports so they don’t fail, or slice you up trying to get them out.

Jumping in here to say I’ve worked with Wylder for quite some time now. He’s quick witted and really knows his stuff!

Are you feeding the leds with 5v or 3.3v? I’ve had issues with 5v and no shift registers as the led won’t pickup the high state of the leddata without a shift register.

https://github.com/WainingForests/zmk-config-xiao/tree/Xiao_rgb I have successfully done LEDS just fine. Per key is a misnomer though. ZMK doesn’t allow individually addressing each key. Instead, you’ll be using underglow to apply effects to the whole “chain.”

Cut it up! Print only thumbs for a while that you can “locate” to a standard set of finger keywells. Do the same for other features you’re wanting to customize.

I can also relatively easily tweak the pcb dimensions if needed to fit. Including switch center to center “flat” distance!

I can do up to 5 rows; infinite columns but a sheet comes with 6.

Oh yeah, handwiring literally is why I spend literal months of time designing over and over the flexible pcbs. I think technically there’s a good 300+ revisions. (Last I checked the old version backup on my cad program was almost a gig worth of saves).

That’s really weird. It should be read only.

I miss the traffic, and volume. This transition really has alot of bumps, but also down with the reddit mess.

Super cool stuff!

I wonder if my flexible pcbs fit in there! If you’d be interested I’d be willing to send you a set of pcbs to see!

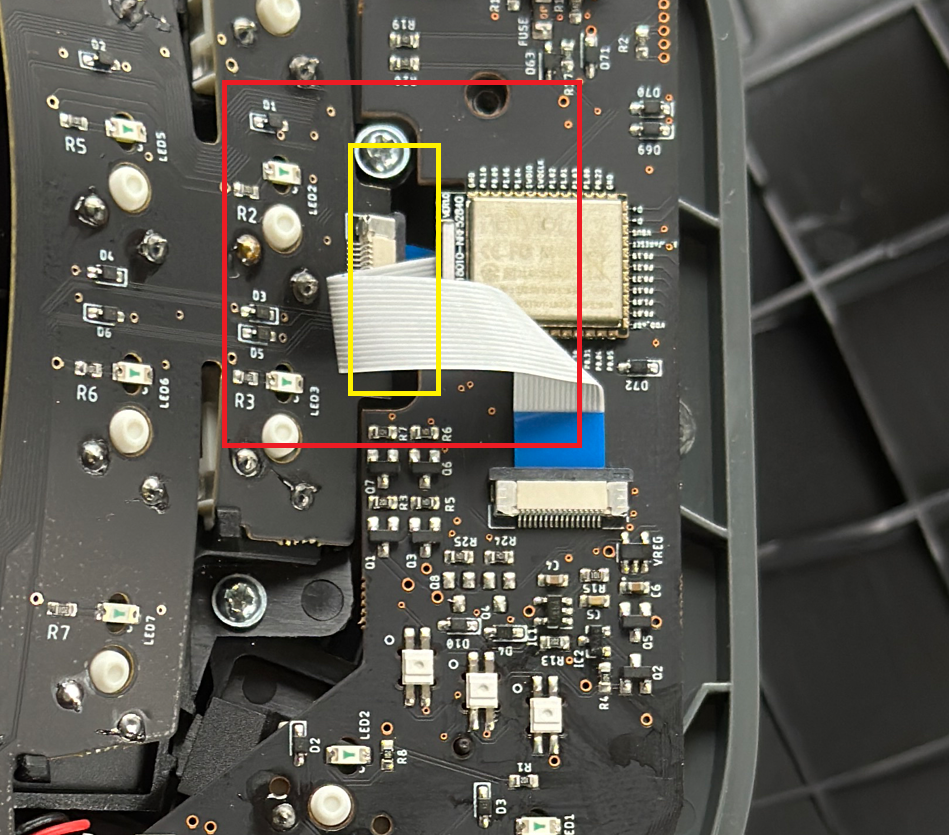

I have some gripes with their design. One side they’re properly positioning the antenna. The other, not so much.

If memory serves this is the right side. The antenna is pointing away from what it cross pares to. It’s got the ribbon cable carrying GND, VCC, Rows and columns violating it’s signal space too.

The best suggestion to resolve this would be to tape down the FPC cable so it’s violating the yellow area as little as possible. But that doesn’t help that it’s pointed the wrong way. Truth be told I don’t know if this is really a fix for their connectivity issues.

I’m just getting into trying the holyiot module they’re using in some of my designs. With other nRF52840 modules I’ve never had signal issues. ZMK does a stellar job. But I don’t know if the 360pro issues are tied to this specifically or something I haven’t seen just yet. Maybe it’s down to their revisions to ZMK? The key press held down is really weird. I wonder if it’s somehow related to power modes being weird on their ZMK.

It might be possible to change the routing slightly.

I’m in the process of building a hotswap option for the 360 and 360 pro boards. 360 is more of a pain in the butt due to their use of shift registers instead of actual diodes. It’s a bonkers and expensive decision if you ask me, but I’m not the multimillion dollar company.

Actual mods:

It depends really on your goals. Compared to the Advantage2 the 360 is like a middle schooler’s science project to a reasonably solid product needing a few tweaks.

You can play around with sound deadening. The boards are naturally pretty heavy so I wouldn’t consider weights. I loved the Haimu heartbeats, the board is silly quiet now. If you’d like I can see if I can get the owner’s perspective on here sometime. Keycaps: I know people swear by the Kinesis caps. I didn’t mind just DSA caps. Though shine through DSA is a little more difficult to get ahold of. I think they offer PBT caps finally so I’d go that route and not worry about it.

Honestly, my changes to a 360pro would be deadening because I’d be opening the case for switch replacement. I’d want hotswap (I hope to offer this in a couple of months), and that’s really it. I’d love to say I’m skilled enough to reverse engineer their thumb + main board. I don’t feel comfortable doing that sadly. I can design a replacement but it would only work on traditional ZMK and would be somewhat expensive.

Side note: Upgrade keyboards selling different batteries seems silly. Firstly, the battery in the 360pro is just as big. It’s well fitted, and the thicker battery likely means longer lifespan (dendrites and stuff not an actual chemist). They’ll possibly tell you about diode stretching, and how it takes them 4+hours for a board replacement. I call BS. But at least they’re “kinesis approved.” There’s nothing in the case / board that denotes tampering. I don’t know how a warranty department would notice any of my work other than the switches themselves are different. I’ve enjoyed upgradekeyboards as a source for supplies for nearly a year, but their kinesis service being 6-9months out is bonkers really.

Thanks! I’m trying my best and my hard work on pcb design seems to be providing pretty good outcomes!