More belt cleanup today.

Before shot.

Yeah, you probably can’t really tell the difference from just this. I mainly had to redo the heights of most of the half-foundations, to set them up that I can just plop my blueprints on them. Also, re-run many of the belts, based on the moved foundations.

I also tore down the leftover temp spaghetti we had, from before I had decided how to get the main facility outputs across the iron ore line here, and over to the shipping lot.

You can see the afterwards results here, much more clearly.

Re-laying out the belts also involved cleaning up this spot, where all the raw resources join up and enter the smeltery building.

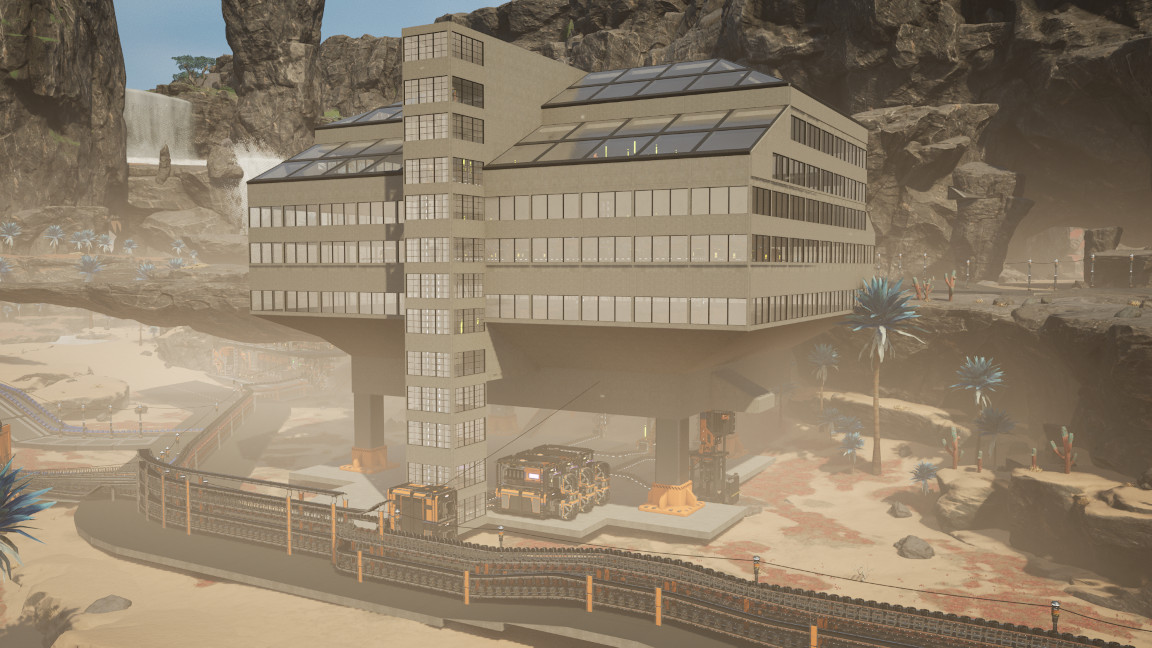

Meanwhile, my wife cranked out more work on the new Ironworks facility, and got it up and running. Should be able to finish out the cosmetics and shipping setup next session.

I thought the thumbnail was sourdough 😠

Oh this is so nice. Me and hubby’s looks so much messier (but we’re due for a big cleanup now we’ve got plastics, we’re planning to make a bunch of re-routable conveyors once we get to making computer chips.

Do you bring all raw materials to the smeltery, or do you have a smeltery per material type?

The smeltery receives Iron Ore, Copper Ore, and Coal, and produces Iron Ingot and Steel Ingot. It also passes Concrete straight through. The Concrete, we figured, was more economical to craft on-site at the Limestine mines, because we’re using 4 of them, and they’re all pure. We would have needed 4 separate Limestone belts, but can merge all Concrete onto just 1.

Thanks, I’m just starting out so playing with different ways of efficient manufacture, good to learn from the experts!